SIPOC Analysis, also known as the SIPOC map, is a simple tool for mapping business processes.

SIPOC is an acronym for the words Supplier, Input, Process, Output, Customer.

SIPOC Analysis is used to map the relationships between the analyzed process, its inputs and outputs, as well as the impact of the customer and supplier on the process. SIPOC is often a part of Green Belt and Black Belt projects. It helps to form a comprehensive understanding of the mutual influences among the examined items.

SIPOC is a part of Lean management methods but can also be used independently. When creating a SIPOC analysis, it is suitable to use brainstorming or other forms of team collaboration.

SIPOC analysis is usually conducted in response to an external trigger. A company realizes that customer expectations do not align with the company's outputs, leading to a need to analyze the entire supplier-customer chain.

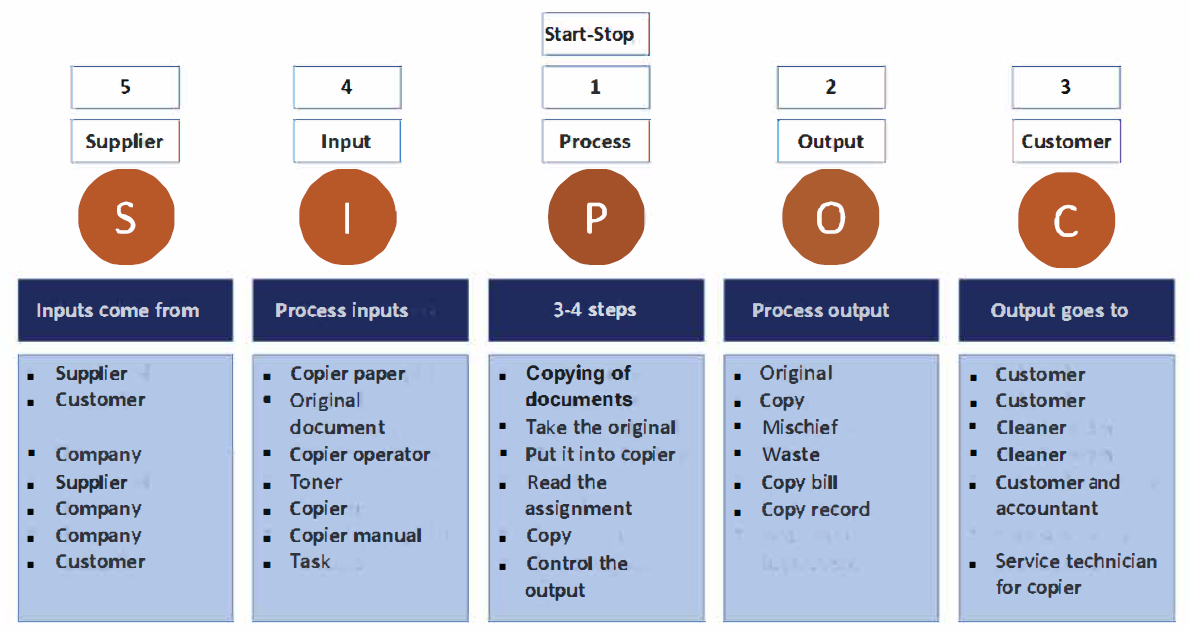

SIPOC is often part of projects conducted using the DMAIC approach and is carried out in the Define phase. SIPOC is created in the form of a table, with column headers representing the analyzed parts of the chain: Supplier-Input-Process-Output-Customer. In other words, Supplier-Input-Process-Output-Customer. It's important to recognize that the chain represents an imaginary path for materials, services, or information that "flows" from the supplier as inputs into the process, where they are transformed into outputs and delivered to the customer.

The analysis begins by defining process steps (filled in the P column). In the second step, all process outputs are described, including non-conforming outputs (filled in the O column). Each output is then linked to a customer in the third step (C column). Subsequently, inputs into process steps are defined (I column), along with their suppliers (S column). The analysis concludes again with the process, identifying areas of the process that might be problematic. The entire analysis proceeds in the cycle of P-O-C-I-S-P.

The SIPOC method serves for a rapid and logical analysis of the customer-process-supplier chain and should be used in a corporate environment wherever issues related to customer dissatisfaction arise, when seeking new customers during company development, or when relationships need to be explained to individuals who are not familiar with them. Although the analysis involves brainstorming, it is essential to accurately define all items. Fuzziness or artificial embellishment are detrimental, as the picture obtained through such means does not reflect reality.

SIPOC analysis is a part of Lean methods and should be applied when there's a need to clarify relationships between the customer, process, its inputs, and suppliers. You can familiarize yourself with SIPOC analysis through some of our training sessions, which you can find below.