Tag is the English term for a label or sticker. In the context of 5S, Red Tag is used to identify items whose necessity is uncertain.

The Red Tag is also utilized within TPM (Total Productive Maintenance) to mark deficiencies on machine equipment that the operator cannot resolve independently.

The Red Tag serves as a visual representation of a problem. In the initial stages of 5S implementation, items are categorized into three main groups during the sorting phase:

The category marked with the Red Tag is typically the largest. Items in this category are functional, but their usefulness is temporarily uncertain. This uncertainty often arises from disorganization and lack of space maintenance before implementing 5S.

The second use of the Red Tag is for visualizing deficiencies in equipment. This tagging system is implemented within the TPM pillar of autonomous maintenance. Operators learn to recognize the machine, its functions, and its current condition, determining whether it is suitable for quality production. They also learn to identify equipment defects. Some defects cannot be resolved independently by the operator (e.g., replacement of specialized parts, electrical interventions, etc.). Identified defects are marked directly on the machine using a red tag, describing the non-conformity and date of identification. Maintenance is responsible for rectifying these issues.

The quantity and placement of red tags reflect the number of problems on the equipment, problematic parts of the equipment, and the degree of care for the equipment.

The Red Tag is a simple tool and is often the first one encountered by employees during 5S implementation.

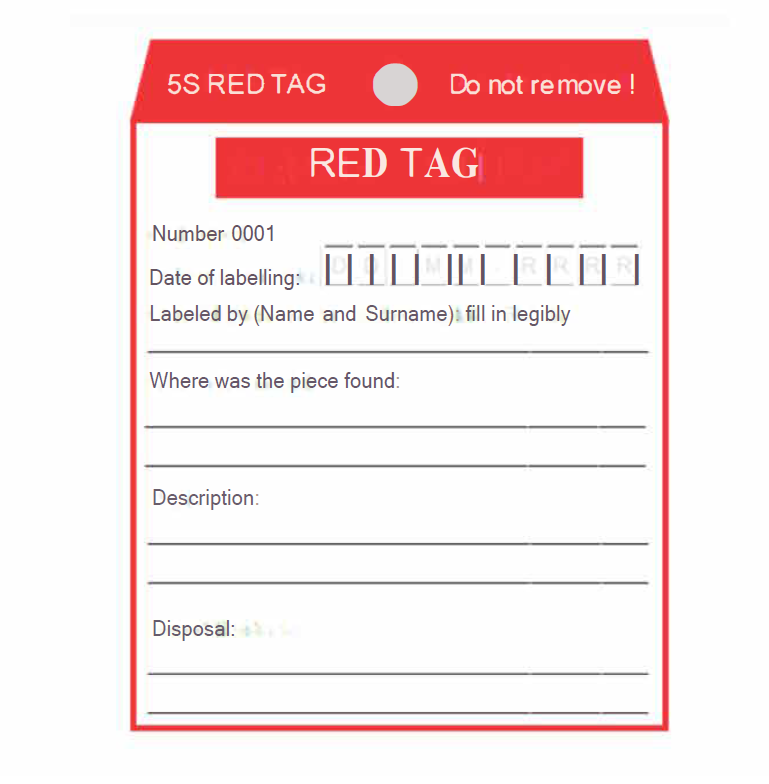

In 5S, the red tag is used to label functional components or tools with an unknown frequency of use. If an item is tagged with the 5S red label, it is stored in a designated area. A maximum storage time is agreed upon in advance, usually around 12 months. The label indicates the item's name, storage location, and date of storage. If someone uses the item during the agreed-upon period, it is classified as necessary and returned to its defined place. If no one uses the item during the agreed-upon time, it is disposed of as unnecessary.

When using the Red Tag to mark equipment deficiencies, the tag will include the date and time of discovering the defect, a brief description of the problem, the location of the issue on the equipment, and the name of the employee who identified the defect. After rectifying the deficiency, the date of correction and the name of the maintenance personnel who resolved it are recorded on the tag.

In modern times, electronic methods for capturing deficiencies are increasingly used. This approach allows for quick analysis based on various categories, such as specific machines, occurrence frequency, type of defect, etc. The recorded information is invaluable for implementing advanced maintenance methods, such as preventive and especially predictive maintenance.

Fig. 1: Example 5S Red Tag

Both 5S and TPM are fundamental methods of lean manufacturing. We can help you implement both methods in your organisation, either through training or tailor-made workshops or projects.

| Training name | Training duration | Venue | Price | The nearest date |

|---|---|---|---|---|

| 5S (7S) – Japanese concept of workplace improvement |

1 day

(8:00 - 14:00)

|

Online |

450,00 €

553,50 € VAT included

|

21.05.2025

|

| 5S - Practical workshop |

1 day

|

Company in-house training | On request |

According to you

|

| TPM - Total productive maintenance |

2 days

|

Company in-house training | On request |

According to you

|