What is QFD - Quality Function Deployment?

QFD is a method of translating customer requirements defined for a product into qualitative manufacturing characteristics of the product.

The author of QFD, Yoki Akao, describes it as follows: "a method for transforming qualitative user requirements into quantitative parameters, deploying functions that create quality, deploying methods to achieve design quality into subsystems and components, and finally into specific elements of the manufacturing process." [1]

What is the purpose of QFD?

To properly understand the voice of the customer, it is essential to realize what the customer expects from the product. In most cases, their requirements are formulated in vague terms, such as "we demand timely delivery of goods." QFD can translate these requirements into measurable characteristics, such as "order processing time" or "production planning time." At the same time, it can identify the relationship between product attributes (strong positive correlation, strong negative correlation), the importance of metrics, and compare product features with the competition.

By understanding the connection between customer requirements (What does the customer want?) and the way to meet those needs (How to satisfy the customer's wishes?), it is possible to optimize production settings to maximize overall customer satisfaction.

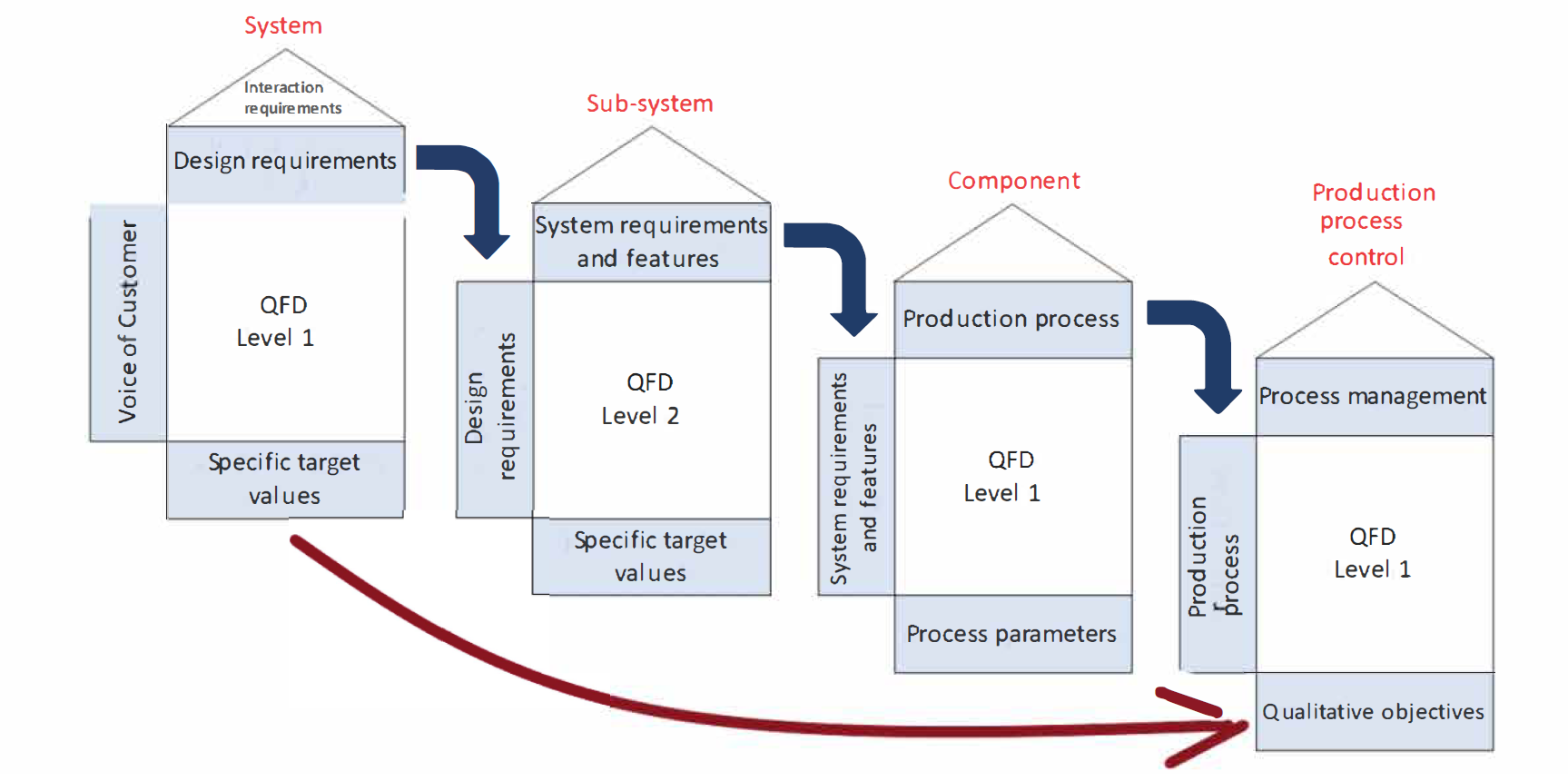

In practice, QFD is usually implemented in four levels, where the outputs of the first level become inputs for the second level. The goal of this approach is to "translate" the voice of the customer, through product design requirements, into system and component requirements and finally into process parameters.

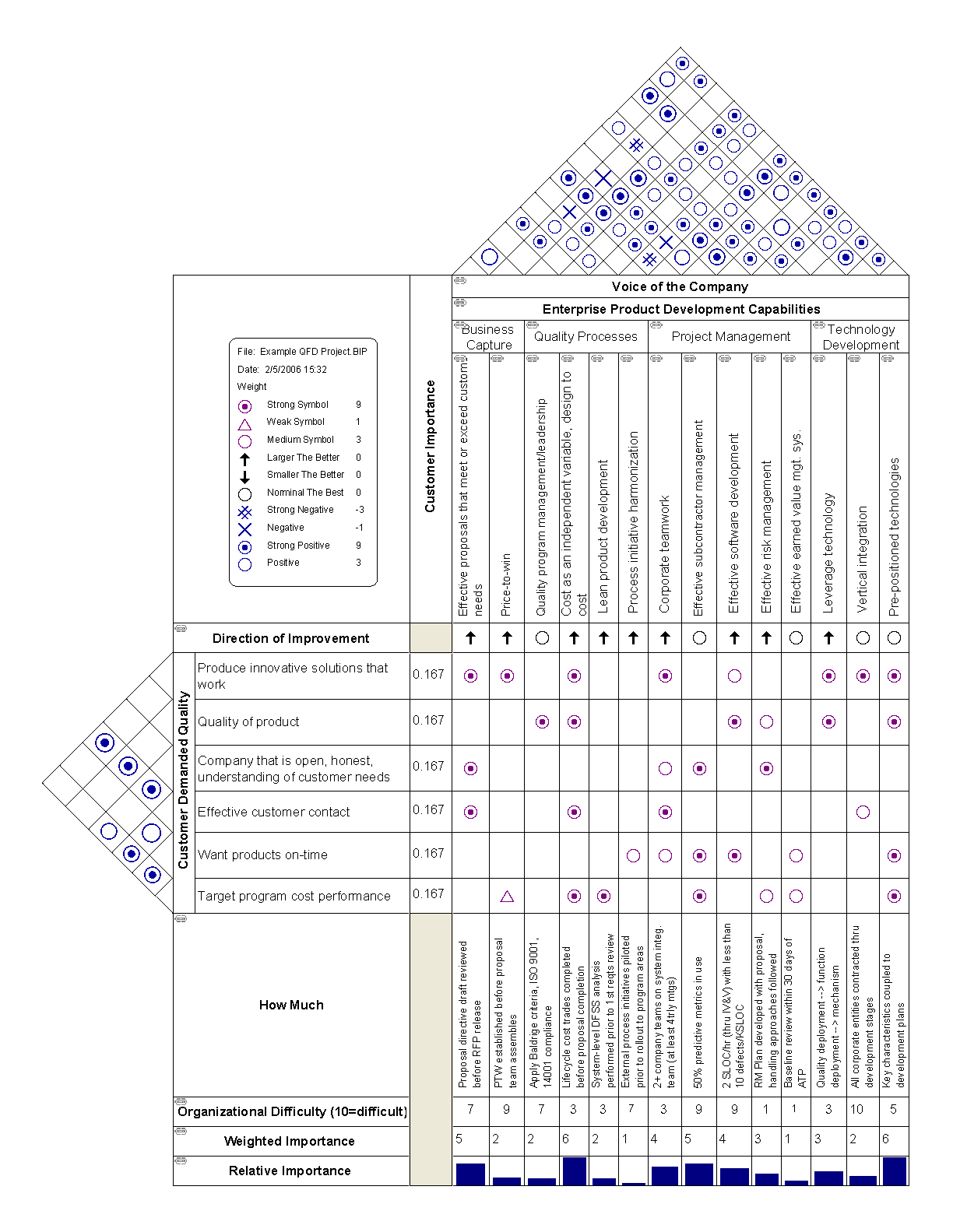

Fig.1: House of Quality

Practical Application

For the practical application of QFD, the so-called House of Quality is used. It is constructed in steps and ideally prepared by a team. The House of Quality is a matrix of customer requirements and qualitative parameters. The following steps describe only the first phase of creating QFD.

Step 1 involves identifying customer requirements for the product (Voice of Customer). In this step, all the requirements that the customer has defined or expects from the product are specified. These requirements form the left horizontal part of the matrix.

Step 2 assigns a certain weight to the requirements. More important requirements have a higher weight.

Step 3 determines the product attributes, which are listed in the upper vertical part of the matrix.

Measurable parameters for each product attribute are listed in the lower part of the matrix.

Step 4 fills in the relationships - correlations, between customer requirements and product attributes. Relationships can be very strong, strong, weak, or none. The team determines the value of the relationship. The strength of the relationship indicates the importance of the product attribute to a specific customer requirement.

Step 5 denotes the so-called roof interactions between individual product attributes, grouped from very strongly positive interaction, through none, to strongly negative.

Step 6 involves comparing the proposed product with competing products available on the market. In practical terms, the relationship between customer requirement (left horizontal part) and satisfaction with the product (right horizontal part) is examined. The relationship is evaluated on a scale from very dissatisfied to very satisfied. The comparison with the competition should include at least two competitive products.

Step 7 calculates the significance of each product attribute based on the product of the importance of the customer requirement and the strength of the relationship to the product attribute. The strength of the relationship was determined in Step 4.

Step 8 divides the attributes and their measurable engineering parameters according to their significance.

This concludes the process of creating QFD, and it continues with the second level, where technical specifications are transferred to the QFD matrix of the second level into the left rows (customer requirements), and their relationship with system and component requirements is examined.

Fig. 2: Stages of QFD creation

How we can help you

Setting up a proper QFD is a fairly complicated process that requires experience and practice. Our company can help you develop a QFD by providing training and organizing workshops.

References

[1]: Akao, Yoji (1994). "Development History of Quality Function Deployment". The Customer Driven Approach to Quality Planning and Deployment. Minato, Tokyo: Asian Productivity Organization. ISBN 92-833-1121-3.