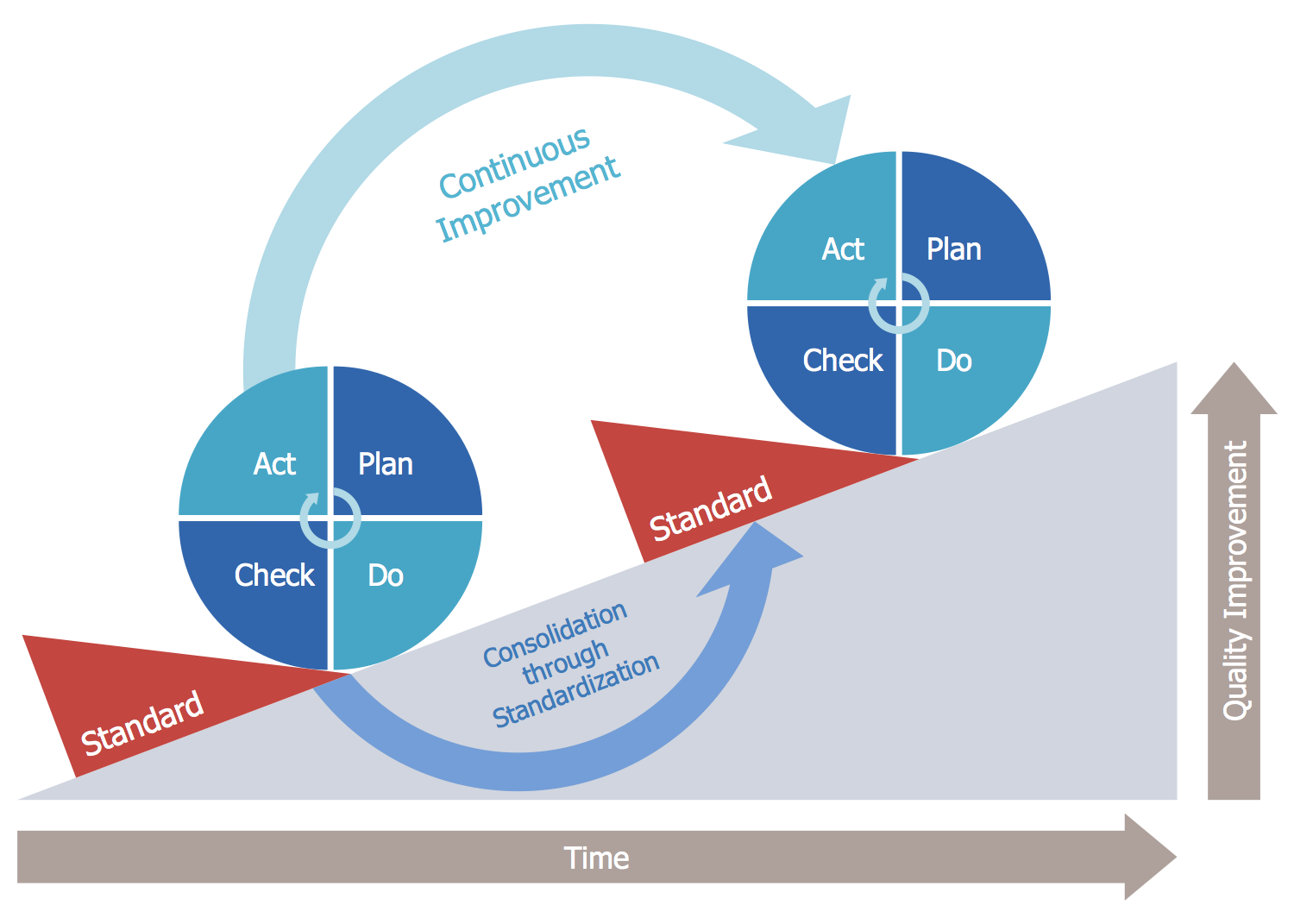

The PDCA cycle is an iterative management method consisting of four steps: Plan-Do-Check-Act. It is used to manage business processes, manufacturing processes, or continuous improvement processes.

PDCA is based on the scientific method of problem-solving: hypothesis-experimentation-evaluation. It serves for the systematic implementation of actions, whose effects are evaluated after implementation and standardized in case of success. It is the fundamental cycle for continuous process improvement and a part of Lean management.

The popularity of the PDCA cycle was achieved by Professor Deming after World War II, the author of modern quality management methods. The PDCA cycle was originally proposed by W.A. Shewhart, and it is sometimes referred to as the Shewhart cycle.

The simple structure of the cycle allows for relatively quick repetitions. During iterations, the state of the system under examination changes to achieve the desired state, and the system iterates towards that desired state. The benefits of small and gradual changes leading to a specific goal include lower implementation costs, minimal losses due to mistakes, and continuous progress towards improvement. The PDCA cycle forms the basis of the Kaizen system, a key tool for continuous improvement, and Lean management.

Image source: https://images.app.goo.gl/FkH4xPcrX74xDA1U6

PDCA can be introduced in a simple way by familiarizing employees with its functioning.

In the first step, Plan, the goal is formulated, the current state is described, and based on a hypothesis about the cause of the problem, actions leading to the improvement of the current state are formulated.

In the second step, Do, corrective actions are implemented, and the system is observed.

In the third step, Check, the achieved results are analyzed and compared with the defined goal.

In the final step, Act, in case of success, the cycle is concluded, and new settings are standardized. The system is observed for a longer period, and preparations for the next cycle begin. In case of unexpected results observed in the Check phase, a new PDCA cycle is started with the aim of eliminating errors from the previous cycle.

Despite its simplicity, comprehensibility, and logic, we encounter failures in practice mainly due to the human factor. PDCA works with assertions and a smaller amount of data, yet improvement cannot be achieved based on erroneous inputs or assumptions. Therefore, both inputs and outputs must be realistic. One drawback is underestimating the Check step, where the output is not sufficiently analyzed, and ineffective corrective actions are prematurely standardized. Another problem is premature termination or halting of cycles due to weak motivation of employees to improve the current state.

The PDCA cycle is a fundamental element of the Kaizen tool, which is part of Lean process management and Lean management. You can familiarize yourself with the PDCA cycle through some of our training sessions, which you can find below.

| Training name | Training duration | Venue | Price | The nearest date |

|---|---|---|---|---|

| Problem solving |

1 day

(8:00 - 14:00)

|

Online |

450,00 €

553,50 € VAT included

|

27.06.2025

|

| TPM - Total productive maintenance |

2 days

|

Company in-house training | On request |

According to you

|

| Japanese methods of improvement according to TPS (Toyota Production System) |

1 day

|

Company in-house training | On request |

According to you

|